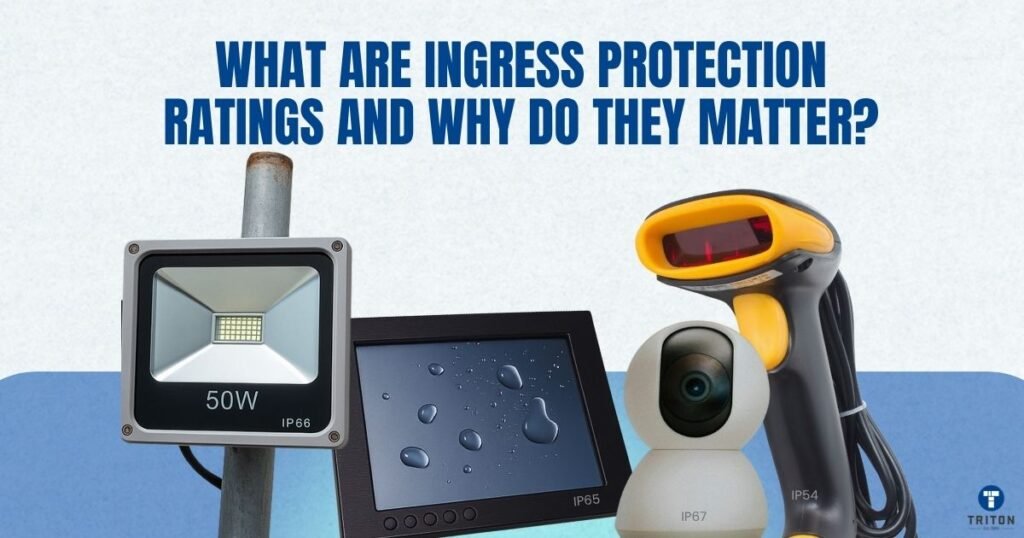

In the intricate world of industrial design and electronic component sourcing, specifying the correct Ingress Protection (IP) rating is a critical decision that balances cost, performance, and application requirements. For engineers and global procurement specialists, understanding the nuanced yet significant difference between IP65 and IP66 ratings—and where they sit within the broader spectrum like IP65 vs IP66 vs IP67—is essential for ensuring product longevity and reliability in challenging environments.

Deciphering the IP Code: A Foundation for Specification

Before delving into the comparison, it’s vital to understand the IP code structure. The ‘IP’ prefix is followed by two digits: the first indicates protection against solid particle ingress (0-6), and the second denotes protection against liquid ingress (0-9K). Both IP65 and IP66 share the highest level of dust protection: “6” signifies complete protection from dust, making them “dust-tight.” The divergence, and the core of the decision-making process, lies entirely in their defense against water.

IP65: Protection Against Low-Pressure Water Jets

The IP65 rating is a robust and widely adopted standard. The ‘5’ in its designation specifies protection against water jets from a nozzle. According to IEC 60529 standards, an enclosure with this rating must withstand water projected from a 6.3mm nozzle from any direction without harmful ingress. This test involves a flow rate of 12.5 litres per minute at a pressure of 30 kPa from a distance of 3 meters for at least 3 minutes.

This level of protection is typically sufficient for applications where equipment is exposed to cleaning processes, rain, or splashing but is not subject to more powerful, direct hydraulic forces. It represents a global sourcing sweet spot for many outdoor electronics, indoor industrial controls near washdown areas, and outdoor lighting fixtures.

IP66: Defense Against Powerful Water Jets and Heavy Seas

Stepping up, the IP66 rating offers a higher degree of liquid ingress protection. The ‘6’ denotes protection against powerful water jets. The testing is more rigorous: a 12.5mm nozzle is used, with a flow rate of 100 litres per minute at a pressure of 100 kPa from a distance of 3 meters for a minimum of 3 minutes. This simulates exposure to heavy seas or very strong jets of water, ensuring the enclosure remains secure under more severe conditions.

Choosing IP66 is crucial for equipment installed in environments prone to tempestuous weather, on ship decks, in areas subject to high-pressure washdown (common in food processing or pharmaceutical manufacturing), or for permanent outdoor installation in coastal or highly exposed locations. It provides a greater safety margin where water exposure is intense and direct.

Key Decision Factors: Application and Environment

The choice between IP65 and IP66 is not about which is universally better, but which is sourced correctly for the specific operational context. Consider these factors:

- Pressure and Directivity of Water Exposure: Will the equipment face directed, high-pressure cleaning (IP66) or general rainfall and incidental splashing (IP65)?

- Environmental Severity: Is the installation in a harsh marine, offshore, or heavy industrial setting, or a more controlled outdoor/indoor environment?

- Total Cost of Ownership: While IP66 enclosures may have a marginally higher initial cost due to more robust sealing requirements, they can prevent far more expensive field failures and downtime in demanding applications. This makes strategic sourcing a key component of value engineering.

The Procurement Imperative: Precision in Global Sourcing

For professionals engaged in global sourcing, particularly on an English-language platform connecting international buyers with manufacturing expertise, precision in technical specification is non-negotiable. Misunderstanding or vaguely specifying an IP rating can lead to product failures, warranty issues, and compromised safety. A global sourcing website in English, based in China, serves as a vital bridge, but its effectiveness hinges on the clarity of the buyer’s requirements. Clearly communicating the need for IP65 (jet-protected) versus IP66 (powerfully jet-protected) enclosures ensures manufacturers can provide accurate quotations and compliant samples.

Furthermore, a proficient supply chain partner understands that these ratings are verified through standardized testing. They should be able to provide or guide you toward relevant test certifications, ensuring the products are not just designed to a standard but validated against it. This due diligence is a cornerstone of professional procurement and mitigates risk in the supply chain.

Conclusion: Specifying with Confidence

In summary, both IP65 and IP66 offer complete dust protection and significant water resistance. The definitive difference lies in the intensity and pressure of water exposure they are engineered to withstand. IP65 safeguards against low-pressure jets, making it suitable for most general outdoor and wash-down-prone indoor applications. IP66, resisting powerful jets, is the requisite choice for equipment facing harsh, high-pressure water exposure.

Making the correct specification requires a clear assessment of the operational environment and partnering with a knowledgeable sourcing provider. For those navigating the complexities of international procurement for enclosures, lighting, sensors, or any external hardware, leveraging a specialized platform can streamline this technical process. To explore a curated supply chain for IP-rated components and electronics, visit lianjer.com.